PRODUCTION MANAGEMENT SOFTWARE

FOR STEEL REINFORCEMENT

Your management solution at a fraction of the cost.

✔ 14-day money back guarantee

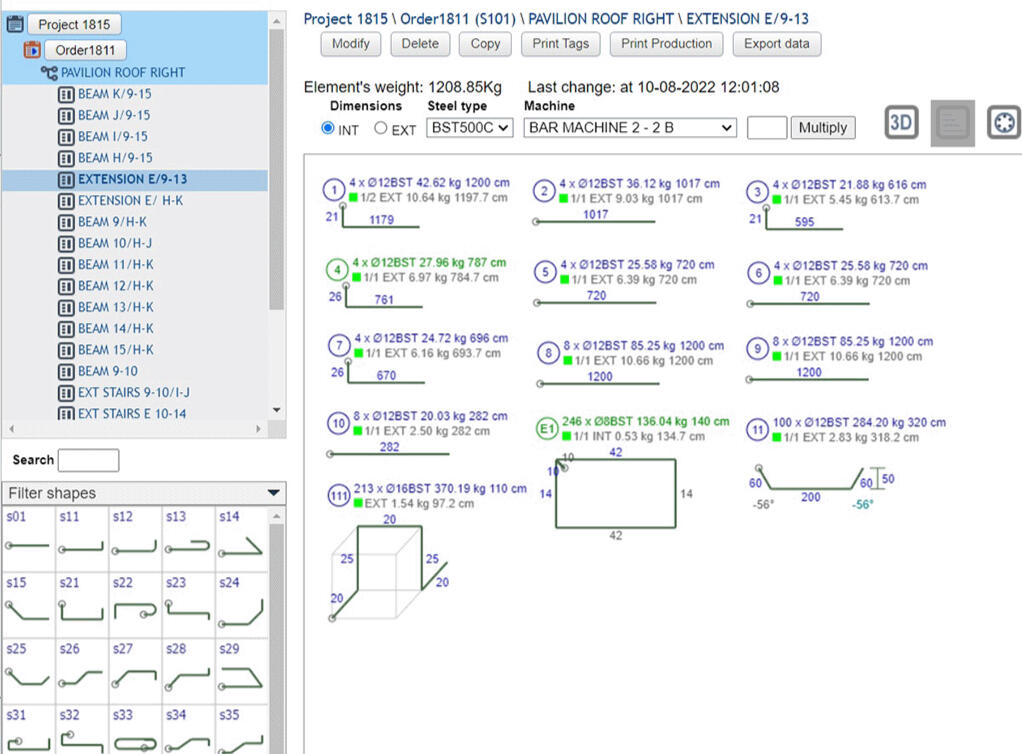

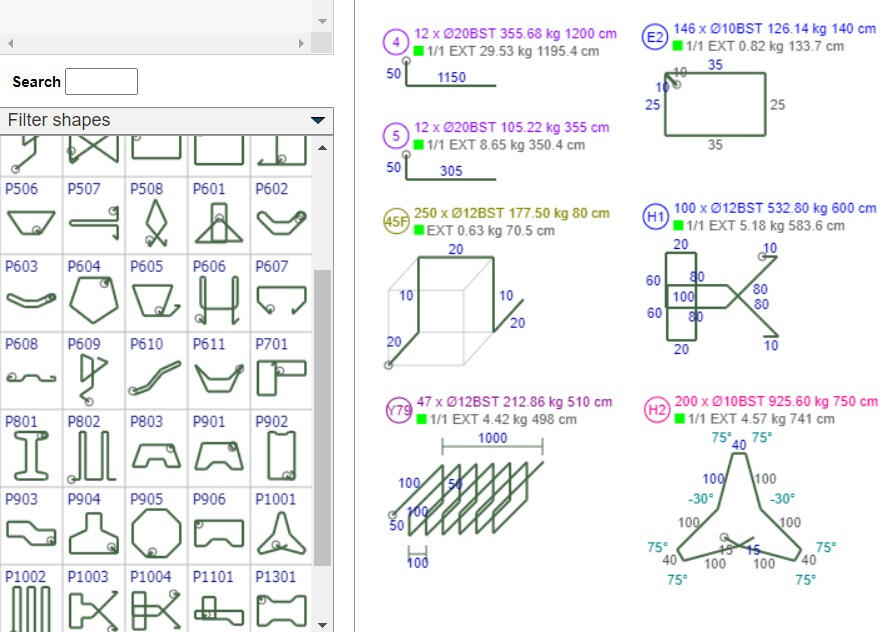

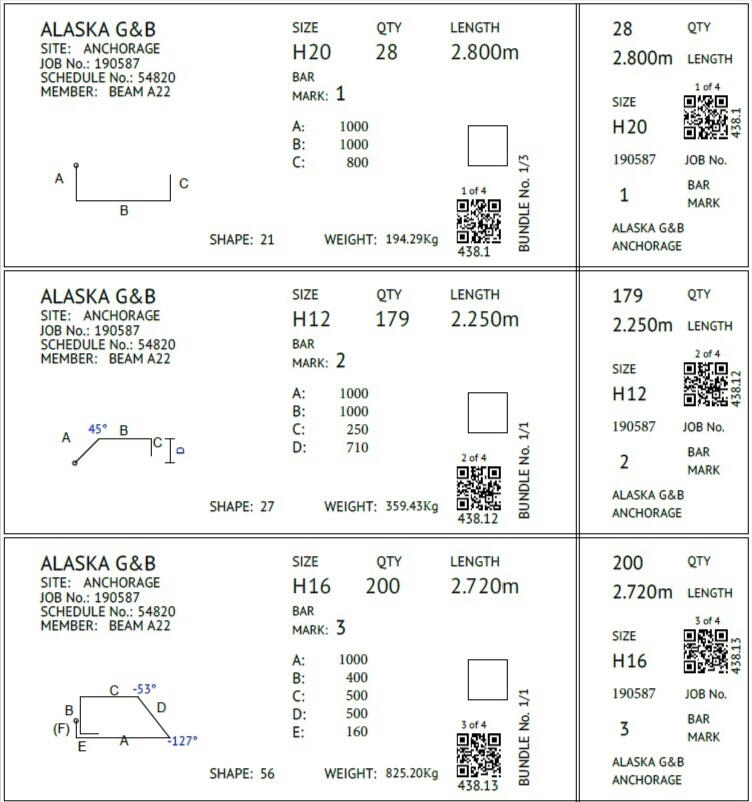

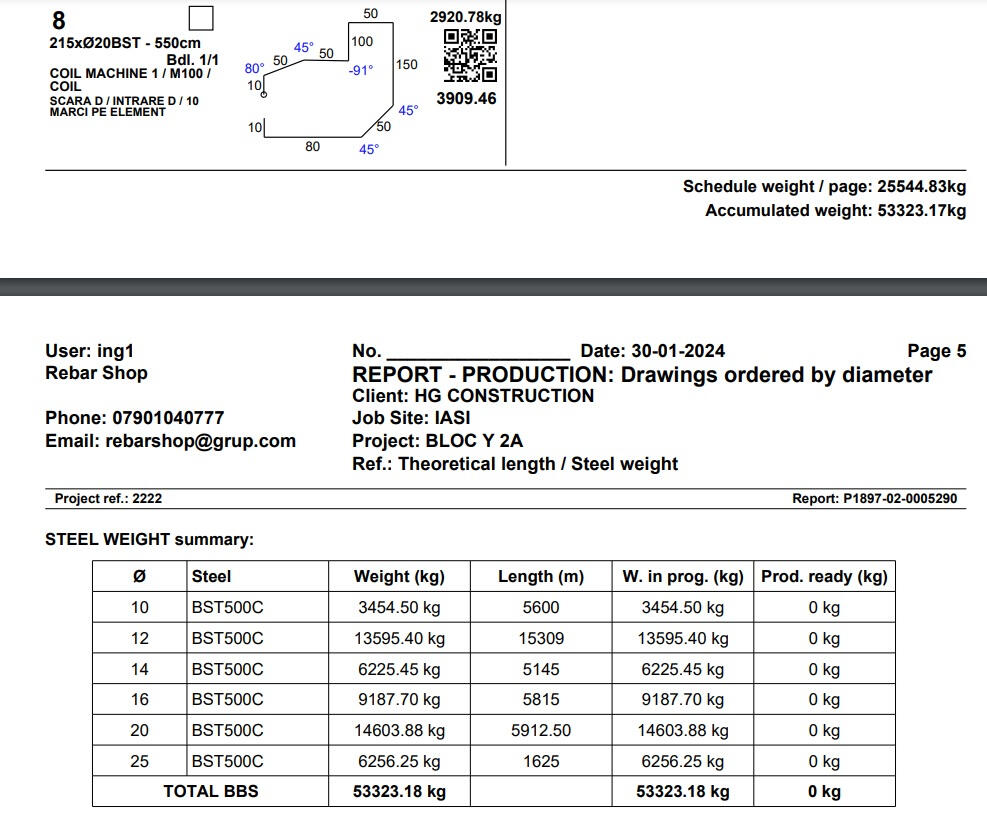

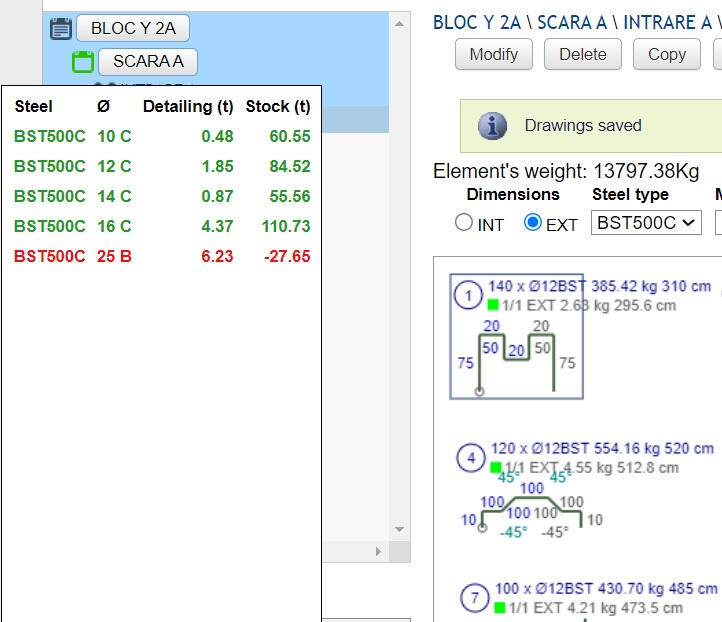

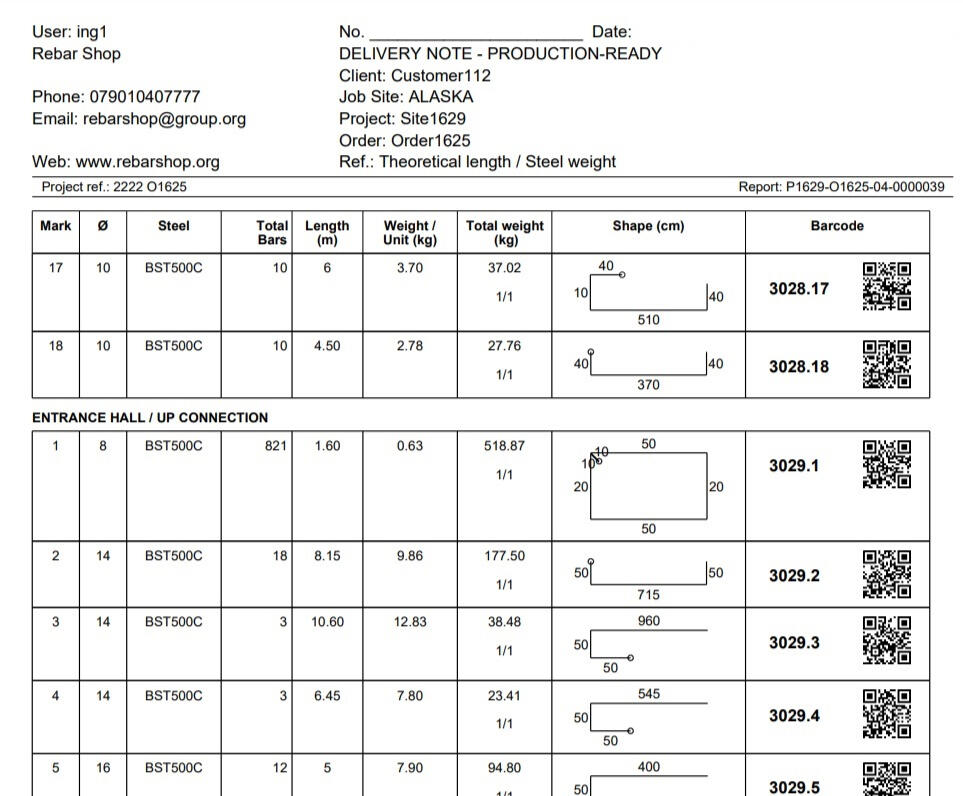

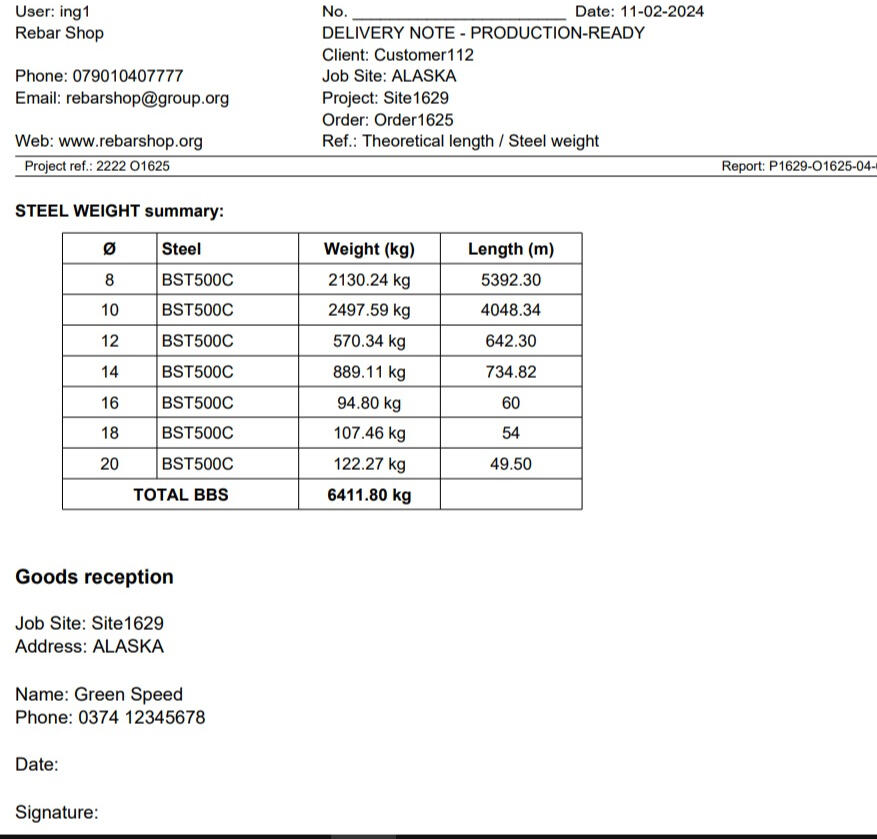

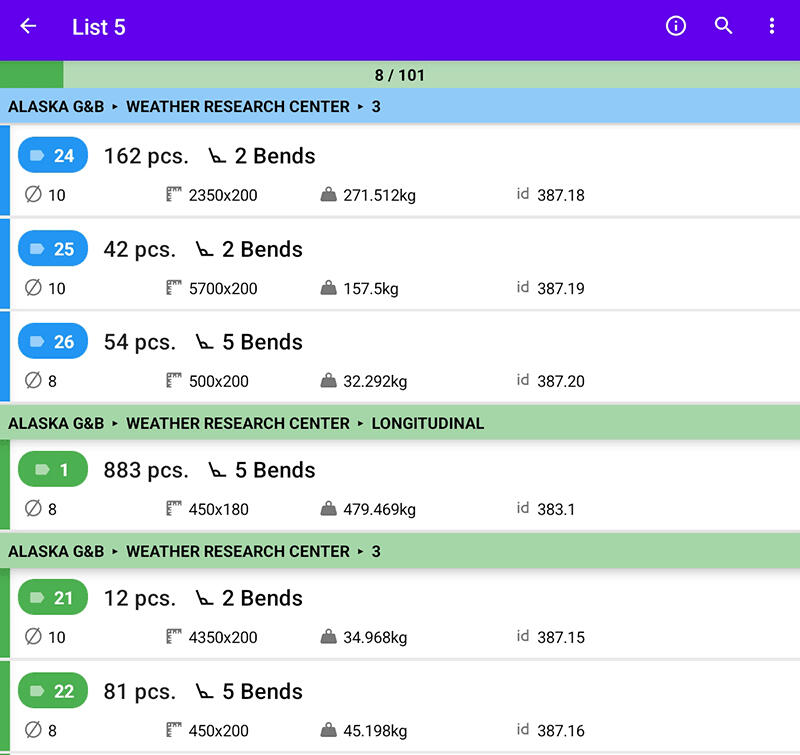

BAR BENDING SCHEDULE MODULE

Turning the plans for a project into a Bar Bending Schedule has never been easier.

How it works

The project is received from the customer.The office generates the purchase order.The purchase order is then forwarded to the customer for approval.

Features

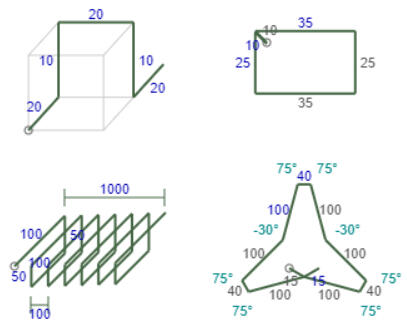

- Complete collections with standard shape codes

- Free drawing of new shapes

- Favorite shapes section for increased efficiency

- Copy/Paste functionality for fast duplication of mark/position, member, and group

- Import/Export orders or projects

- Automatic theoretical and production lengths calculation

- Automatic angle calculation for inclined shapes and couplings

- Automatic calculation of external dimensions from internal dimensions and vice versa

- Production weight calculation according to mandrel bending radius

- Support for variable shapes, 3D shapes, helix, piles and mesh with automatic calculation of length and weight

- Bundle system: split a mark/position in bundles and load it in multiple trucks

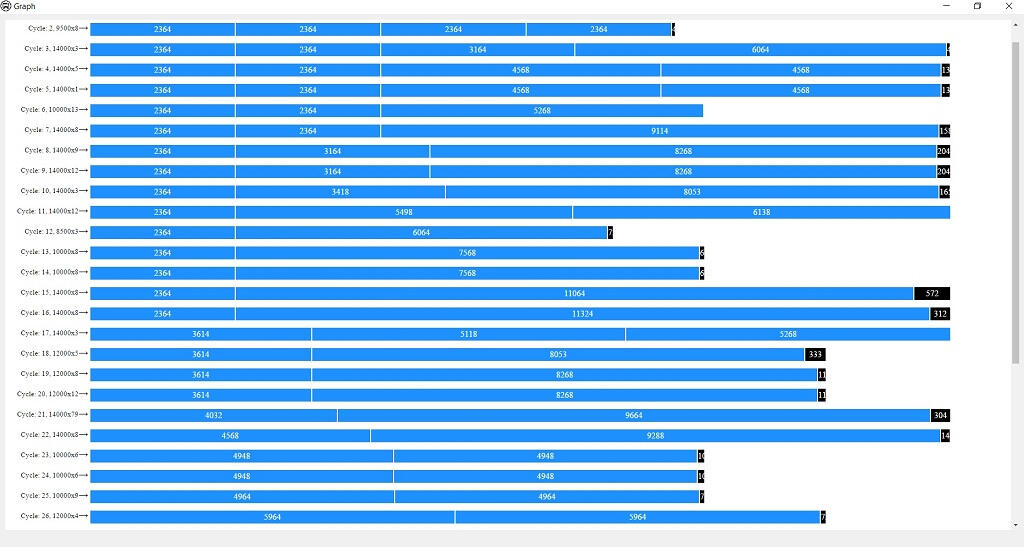

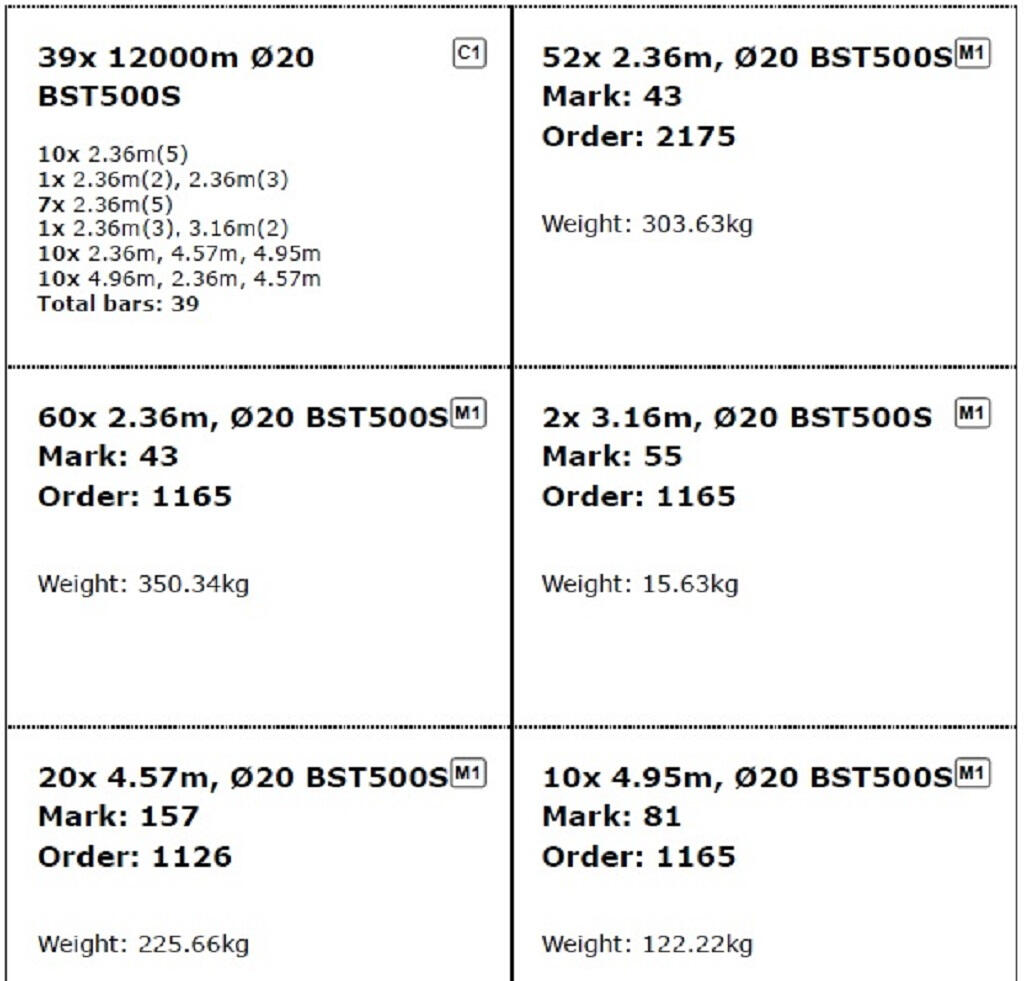

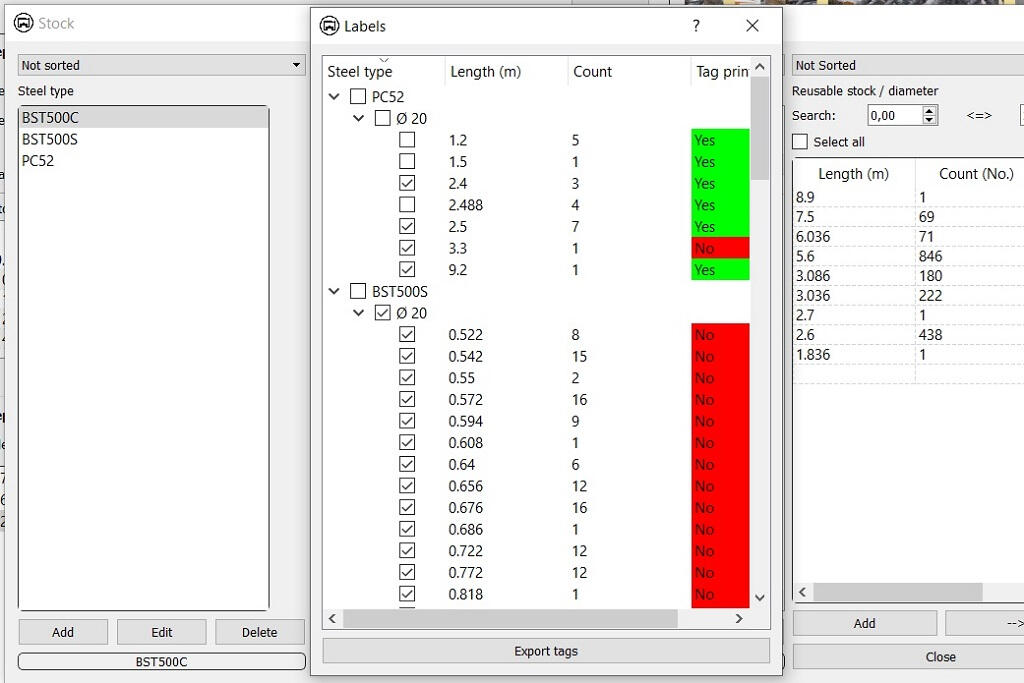

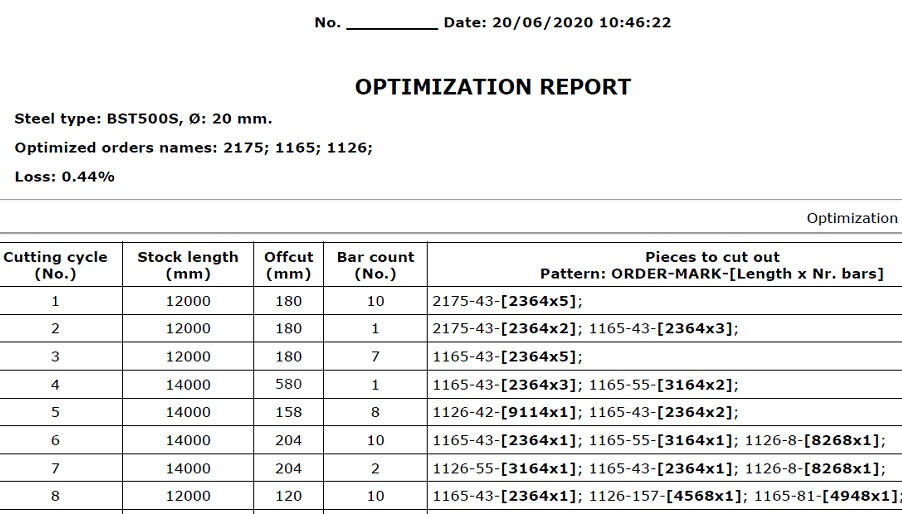

CUT-TO-LENGTH OPTIMIZATION

Optimize steel stock procurement and minimize waste through cut-to-length optimization simulations.

How it works

Select the orders for cut-to-length optimization.Import the bar lengths for optimization.Set the standard steel stock lengths to optimize from.Set the reusable steel stock lengths if they exist.Run the optimization and send the cut-list to the machine operator.

Features

- Multi-order optimization

- Filter lengths by steel grade, diameter, length range

- Automatic import of bar lengths for optimization

- Multi-stock lengths optimization

- Optimization simulations for best steel length procurement

- Graphical or list representation of optimization result

- Optional cut-list tags for easier material handling

- Optional reusable bar labels

- Stock updates after each optimization

- Complete optimization summary reports

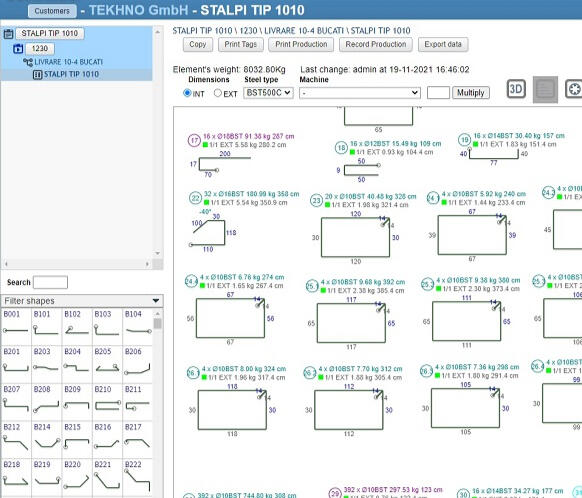

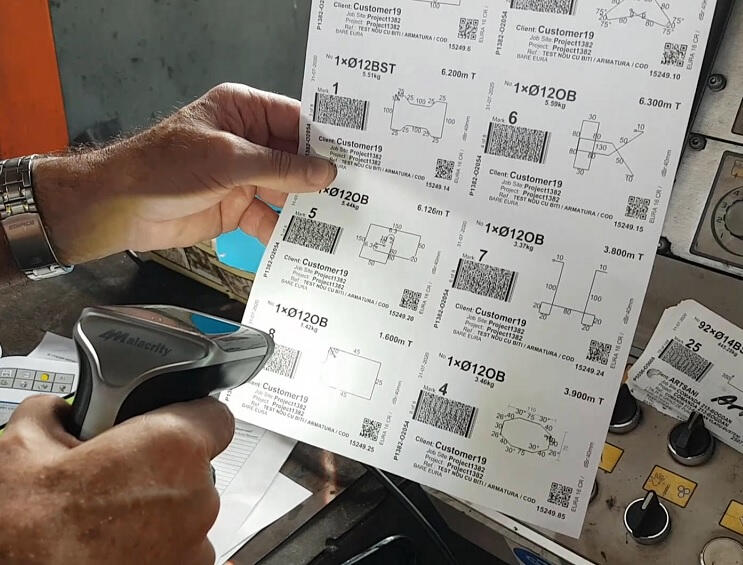

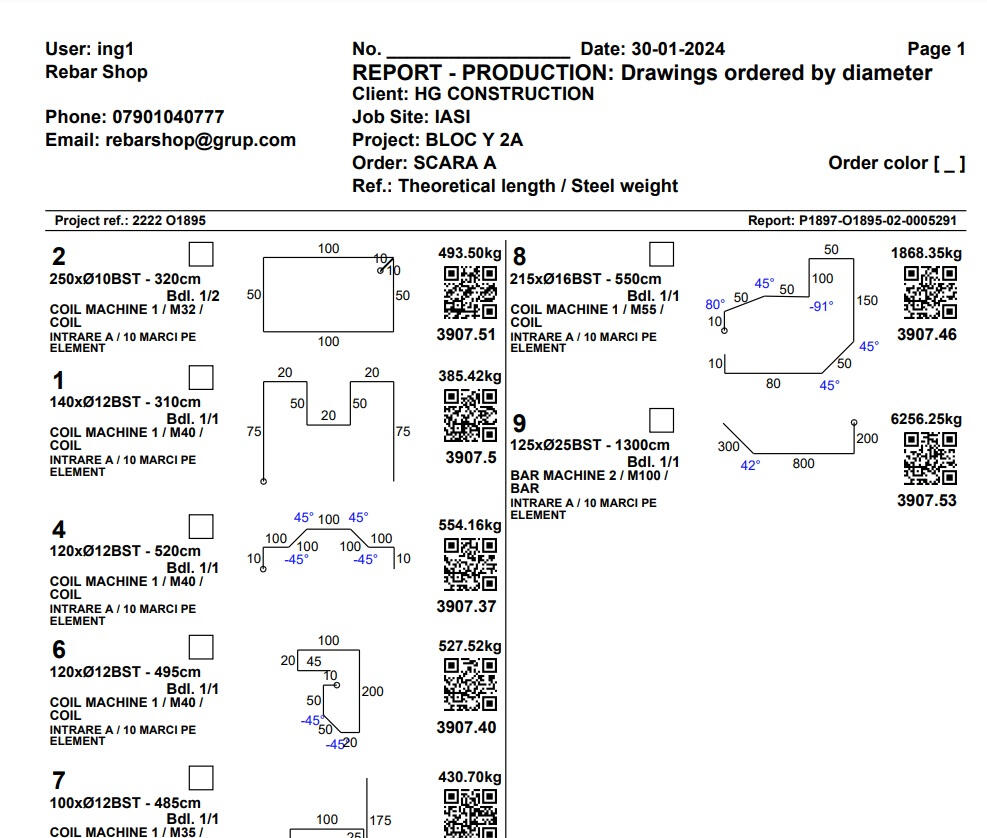

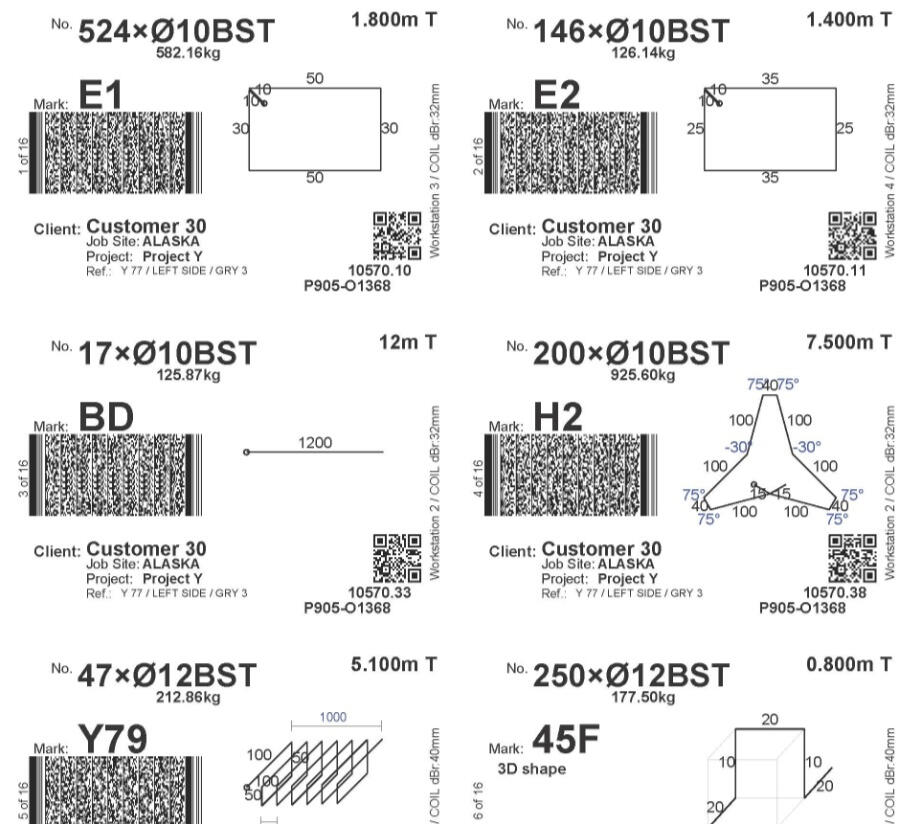

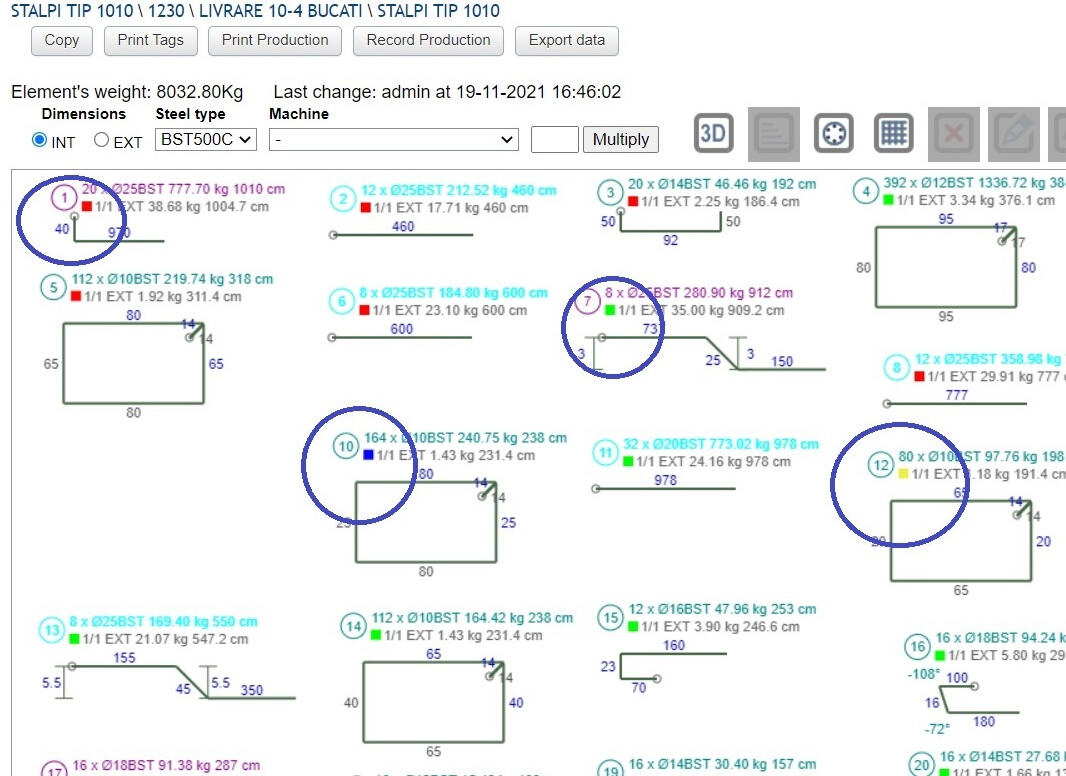

PRODUCTION START

Increase productivity using error-free bar bending scheduling and eliminate down-times, improving customer satisfaction and increasing profitability.

How it works

After the customer approves the purchase order, production planning starts.The office schedules order production according to the current production load.

Production tracking helps the office accurately determine machine load.Order production is scheduled based on customer priorities.The software groups tags by diameter, machine, or position before the office prints them.Production initiates once the machine operator receives the tags.

Features

- Machine specialization based on steel diameter

- Automatic mark/position allocation on machine based on production output

- Display both theoretical and production length/weight

- Add percentage to the individual theoretical weight of each project

- Print machine barcode tags (automatic send mark/position geometry to machines)

- Error prevention: forbids printing tags for already finished production

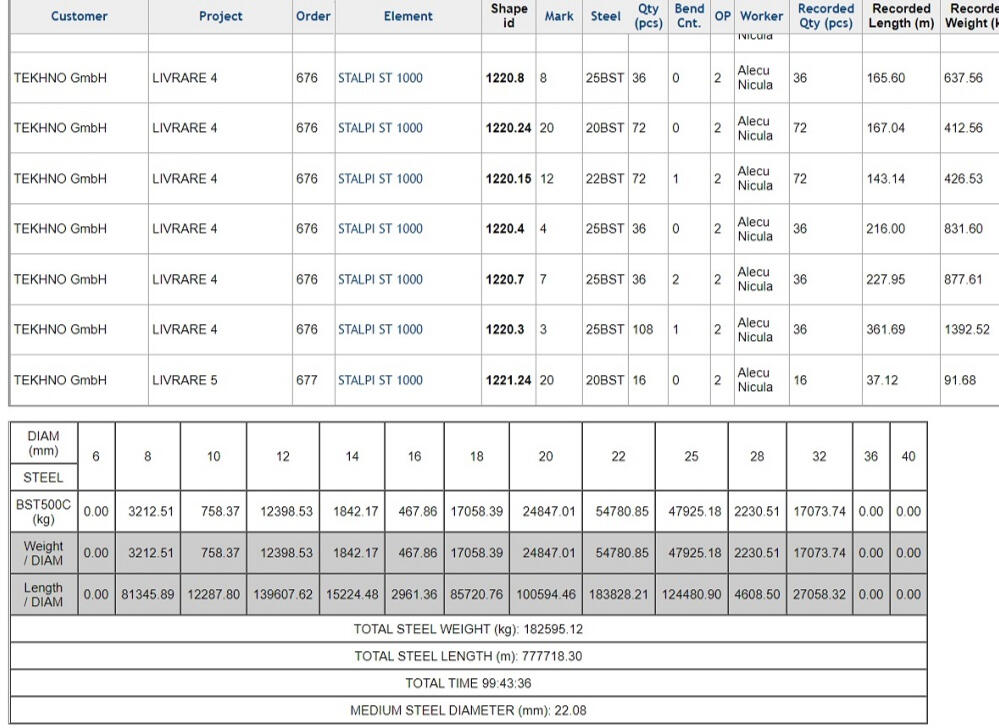

- Production and steel summary reports per steel type and diameter

- Automatic export of bar lengths for optimization

- Steel stock report

- Machine production report

- Operator production report

- Steel procurement report: calculates required steel stock for uninterrupted production

- Real-time steel stock warnings

✔ 14-day money back guarantee

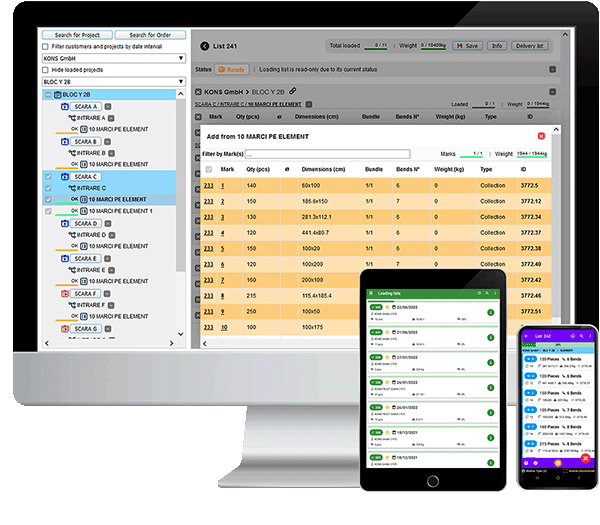

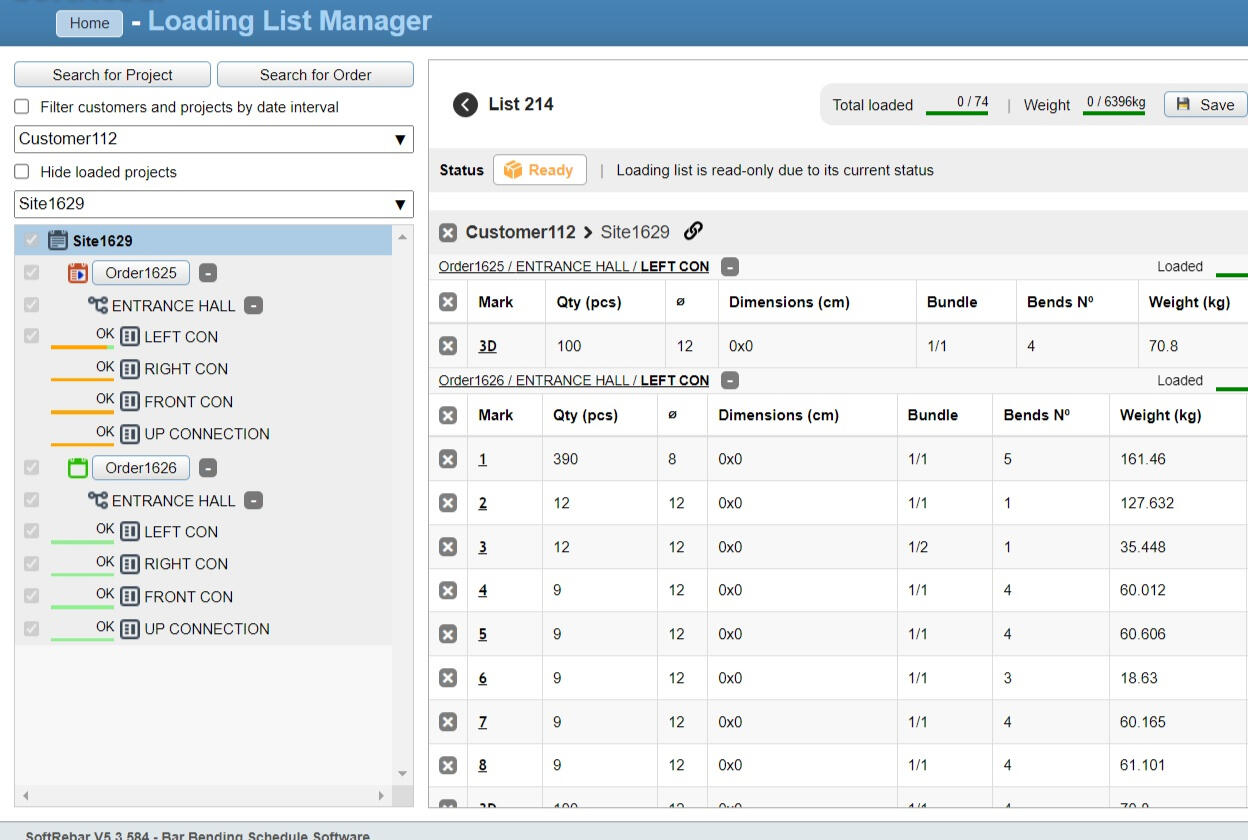

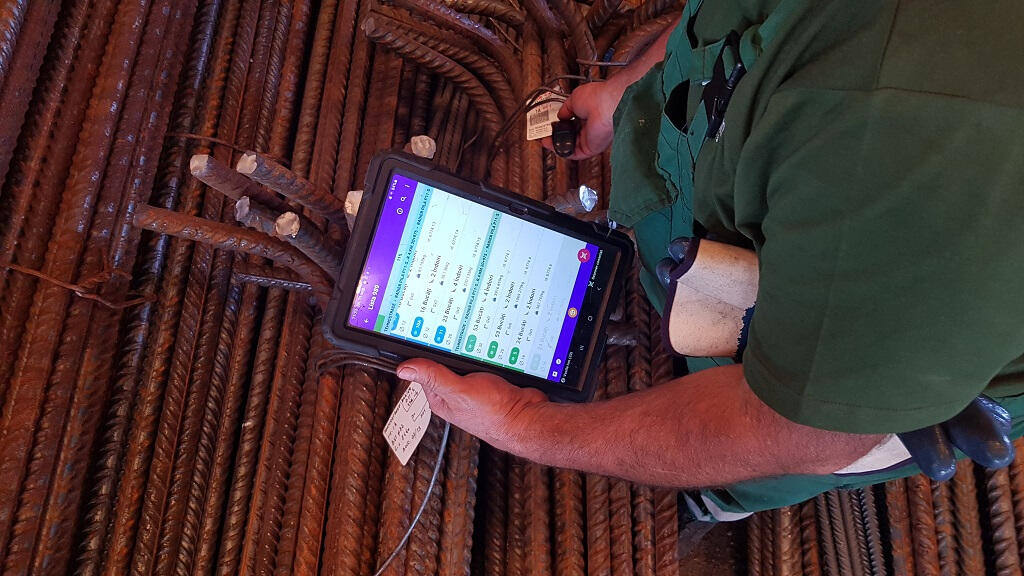

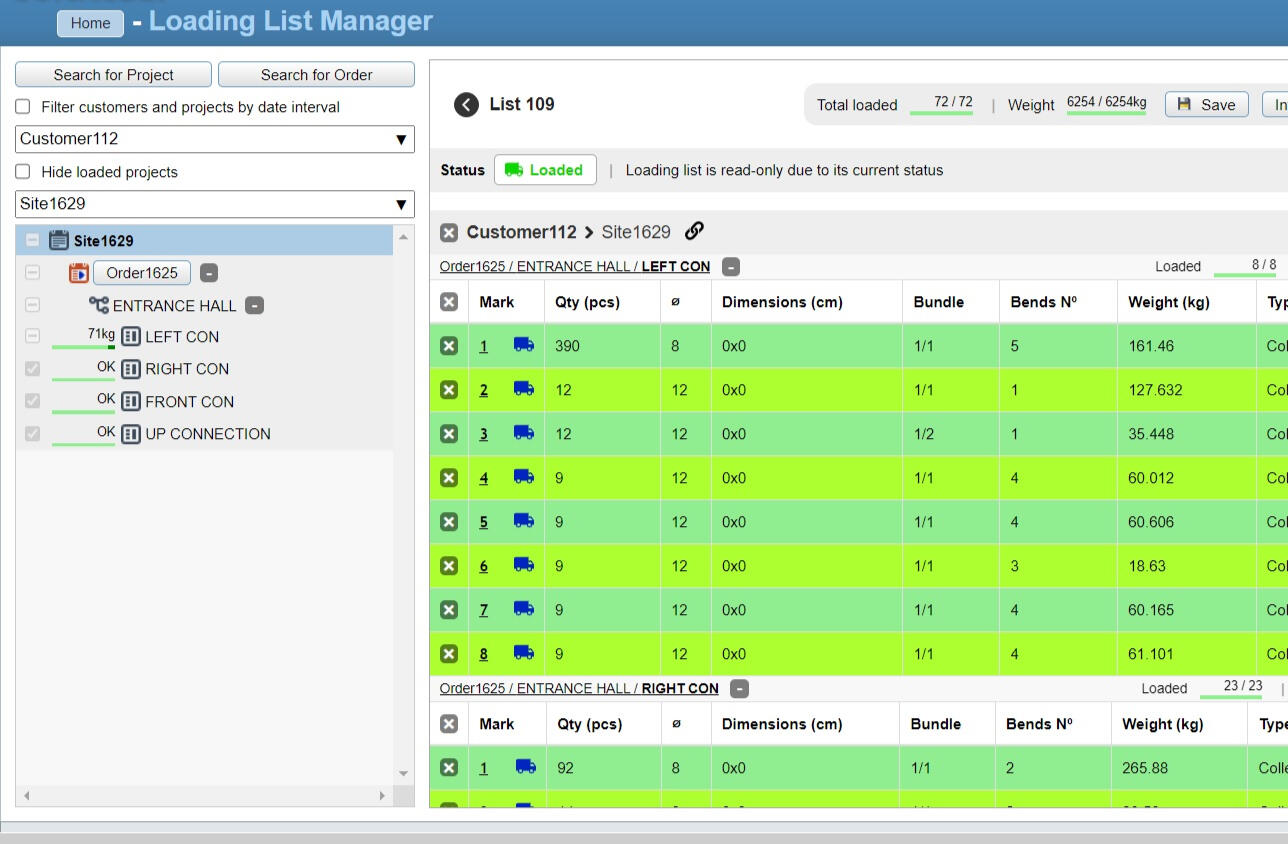

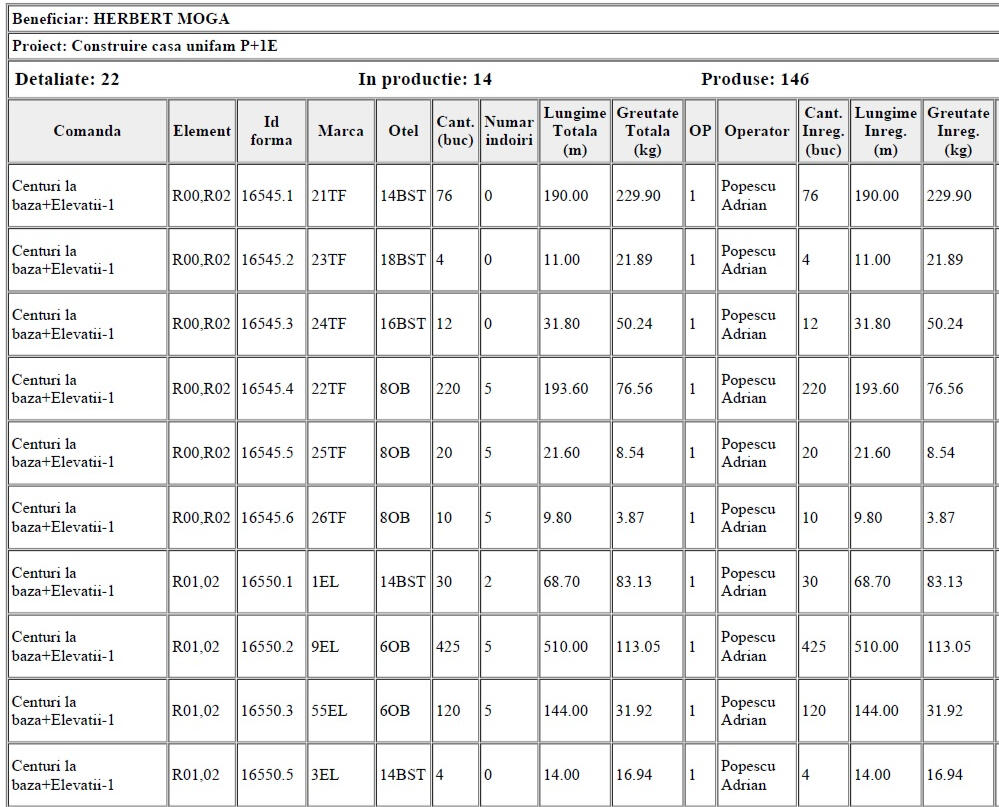

TRUCK LOADING AND DELIVERY WITH BARCODE SCANNING

A fast and error-free way to track order deliveries.

How it works

According to delivery priorities, the software creates loading lists.A list contains all mark/positions required for loading on a truck. Each mark/position includes complete loading information: client, project, dimensions, shape image, etc.A loading list can include more clients, projects, or orders. The software generates separate delivery documents for each client.Automated calculations determine steel weight and the required number of trucks for every project.A loading lists has three stages:

- Draft: editable until all project details are set. Represents work in progress.

- Ready: accessible via an Android tablet by the delivery manager.

- Loaded: confirms all contents are successfully loaded onto the truck.The office has flexibility to change lists as needed.

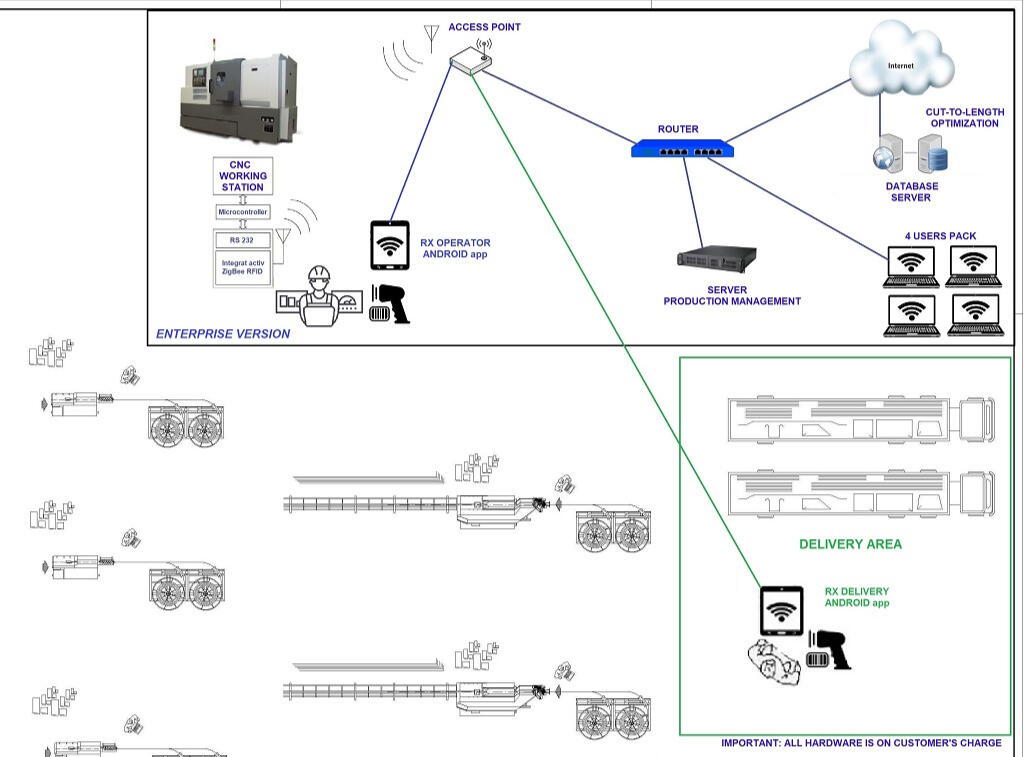

Delivery managers use a special designed Android application (RxDelivery) and scanner to confirm the loading of each mark/position.

Accessing current-day loading lists requires a unique ID login. All loading activitiy is recorded under the manager's ID.Loading occurs via scanning tags or tapping the tablet's screen. Once all marks/positions are loaded, the list status changes to loaded.

Delivery managers can adapt loading lists according to factory conditions.Electronic loading validation minimizes post-delivery complaints.

Features

- Unique ID system for delivery managers

- Delivery manager activity tracking

- Real-time load tracking

- Mark level delivery tracking

- Multi-client, multi-project or multi-order loading lists with separate delivery documents

- Automatic calculation of steel weight and required number of trucks

- Eliminate unnecessary communication.

- Standardize the delivery process, prevent errors and improve efficiency

- Fast generation of quality delivery documents

- Advanced reporting

✔ 14-day money back guarantee

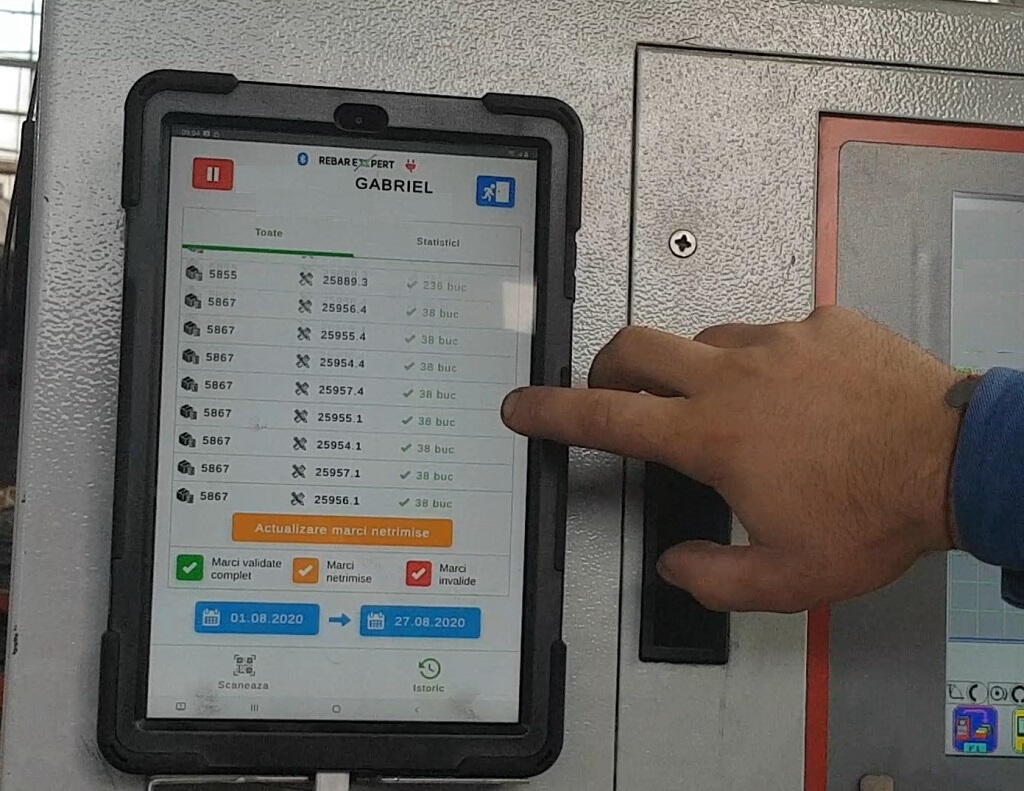

REAL-TIME PRODUCTION TRACKING

Instant visibility into the production process, facilitating timely decision-making and maximizing productivity.

How it works

Each machine gets allocated an Android tablet.The machine operator logs in the special designed Android application (RxOperator) using his unique id to start the production session.

The machine operator scans each mark/position tag using a barcode scanner connected to the tablet.

The system can record more operations on the same mark/position, like cutting at one machine and bending at another.

The tablet sends all production details to the server: operator name, machine, time, quantity, etc.The server generates advanced reports for: machine, operator, steel stock, etc.The steel stock is accordingly adjusted when a mark/position is produced.Real-time production tracking ensures complete steel traceability with maximum accuracy.

Features

- Machine operator activity tracking (both production time and break time)

- Machine production efficiency

- Real-time production tracking at the mark/position level

- Complete steel traceability at the mark/position level

- Automatic steel stock adjustments based on production data, deducting used stock from inventory

- Increased productivity

- Eliminate unnecessary communication

- Advanced real-time production reports: operator, machine, steel stock

✔ 14-day money back guarantee

PRICING

MONTHLY PRICING

10% discount applied

STANDARD

€150/mo

€150/mo

Bar Bending Schedule

Import/Export project, order

Cut-to-length optimization

Steel inventory

Machine barcode tags

Machine/Operator manager

Machine/Operator reports

Production reports

Online training

1 user

PRO

€250/mo

€250/mo

Bar Bending Schedule

Import/Export project, order

Cut-to-length optimization

Steel inventory

Machine barcode tags

Machine/Operator manager

Machine/Operator reports

Production reports

Loading and delivery

RxDelivery app for 1 tablet

Online training

1 user

MAX

€350/mo

€350/mo

Bar Bending Schedule

Import/Export project, order

Cut-to-length optimization

Steel inventory

Machine barcode tags

Machine/Operator manager

Machine/Operator reports

Production reports

Loading and delivery

RxDelivery app for 1 tablet

Real-time production recording

RxOperator app for 1 tablet

Online training

1 user

100% money back guarantee

If the software does not meet your expectations within 14 days from purchase, we'll issue a full refund.

SOME OF OUR CUSTOMERS

TESTIMONIALS

RebarSoft has transformed our production process, making it more organized and reliable when delivering to job sites.

David, Viking

The team behind RebarSoft has greatly increased our rebar shop's productivity and efficiency. Now, we are able to reward our machine operators based on their performance.

Bogdan, Eurozone

Since using RebarSoft's BBS and tags, we've gained more clients through word of mouth.

John, SteelWrks

Thanks to RebarSoft's electronic loading validation by scanning, we can now efficiently verify the accuracy of our deliveries.

Alex, Cavilas

At first, we were hesitant, but the RebarSoft team clearly communicated the benefits and provided step-by-step guidance during implementation.

Robert, Presto

With RebarSoft, we finally have access to information for every step of production, giving us greater control and oversight.

Sarah, VelocitySteel

FAQ

Why buy RebarSoft?

RebarSoft is a comprehensive rebar management software developed by a team of rebar professionals with over 15 years of experience in the construction and reinforcement industry.

RebarSoft was built to solve many problems related to the production of steel reinforcement, while receiving feedback from clients around the world.

RebarSoft features include effortless order entry, production, and material tracking, benefiting construction companies, cut and bend factories, reinforcement detailers, engineering firms, and placing firms worldwide.

All RebarSoft packages include free software training and support services. It is backed and collaborated on by multiple companies globally.

What happens after payment?

You will be sent an email with the connection details required to access the service.

Training sessions will be scheduled within 24 hours of payment receipt. If you haven't received an email from us by then, please contact us at sales@rebarsoft.net.

How is the service provided?

The service operates on a Software-as-a-Service (SaaS) model, allowing users to access it remotely via the internet using a web browser. Hosted on secure servers, users can log in from anywhere with internet access.

Is the hardware (tablets, scanners) included?

Hardware is not covered in the price and it is the customer's responsibility.

Can I get more users?

Additional users are available at €25/user/mo.

How many machines are included?

Each package includes 2 machines. Additional machines are available at €25/machine/mo.

Can I get RxDelivery or RxOperator on more tablets?

Additional RxDelivery or RxOperator installations are €25/tablet/mo.

How to customize the tag layout?

Based on your needs, we provide free-of-charge customization of tag layout.

Is there a non-subscription option available?

We offer an enterprise version which is not subscription based. Contact us for a quote.

Do you offer a free trial?

While we do not provide a trial version, we do offer a 14-day refund policy.

Do you have a refund policy?

We do have a 14 days refund policy so that you can buy with confidence. Refunds are typically received in 10 days after being processed.

Do you offer training?

We offer 5 hours of online training for all packages. Additional training is available for a fee.

Do you offer support?

For any issues, we're here to assist you whenever you need us.

Can I upgrade plans later?

Yes, you can upgrade plans anytime and pay only the difference.

When does the service renews?

The service will renew monthly/yearly on the date of the initial subscription.

What happens if I don't renew?

Upon service suspension, you will have a grace period of 30 days before your information is deleted.

How do I cancel my subscription?

The email with the access details will also include instructions on managing your subscription.

Is there any tax paid on top of the price?

Depending where your business is located additional taxes might apply. If you are in Europe and provide a valid VAT number, there won't be any additional taxes.

Is the payment method safe?

All transactions are securely processed by Stripe.

What payment methods do you offer?

Stripe provides a wide range of payment methods, ranging from credit cards to country-specific options. The available payment methods are displayed on the checkout screen.

CONTACT

Sales office

Dynamiq Tech Limited

Cambridge, United KingdomEmail: office@rebarsoft.net

Whatsapp/Viber/Telegram: +447355828909

Sales and software development

Pyrognomic Software SRL

Bucharest, RomaniaEmail: office@rebarsoft.net

Email: support@rebarsoft.net

Whatsapp/Viber/Telegram: +40723311158

Software development

Mega Code Eood

Sofia, BulgariaEmail: support@rebarsoft.net

An email receipt including the details about your order has been sent to the email address provided during checkout. Please keep it for your records.

For any issues: office@rebarsoft.net